The challenge of unique workflows with out-of-the-box ERP systems:

ERP systems, out-of-the-box, are designed to support inventory management processes for a broad range of companies, from five people on the shop floor to 500. But manufacturers are different and sometimes their ERP system is not flexible to meet the specific roles and rules in their inventory control operations.

Epicor’s ERP inventory management tools are well-designed for typical applications – but not necessarily for your unique business operations. When Epicor doesn’t fit your needs perfectly, TwinEngines recommends integrating specialized tools with Epicor to handle your unique workflows. Inventory counting is one of those business operations.

Performing physical inventory counts and cycle counts are constant challenges. No company likes to spend time counting parts, nor do employees. The trick is to make it painless.

The TwinEngines Inventory Count accelerator – TwinEngines developed a Physical Inventory Count solution that makes counting inventory easier for manufacturers using the Epicor ERP system. Manufacturers conduct “mini” physical inventories, treating them as cycle counts. Instead of configuring Epicor to generate part numbers at specific locations to count, they choose the bins and parts to count and employees move through the warehouse counting. There are no tags. This makes cyclical or departmental counts much easier.

We maintain our Physical Inventory Count accelerator as a ready-to-run module and then customize it to support your unique inventory control strategy.

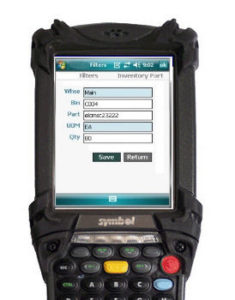

For shop floor and front office – The accelerator consists of a mobile application for warehouse employees and a web application for the front office. A custom database resides in the Microsoft SQL Server serving the Epicor ERP system. The entire solution is part of the TwinEngines workflow platform that integrates Epicor with your unique business model and manufacturing needs

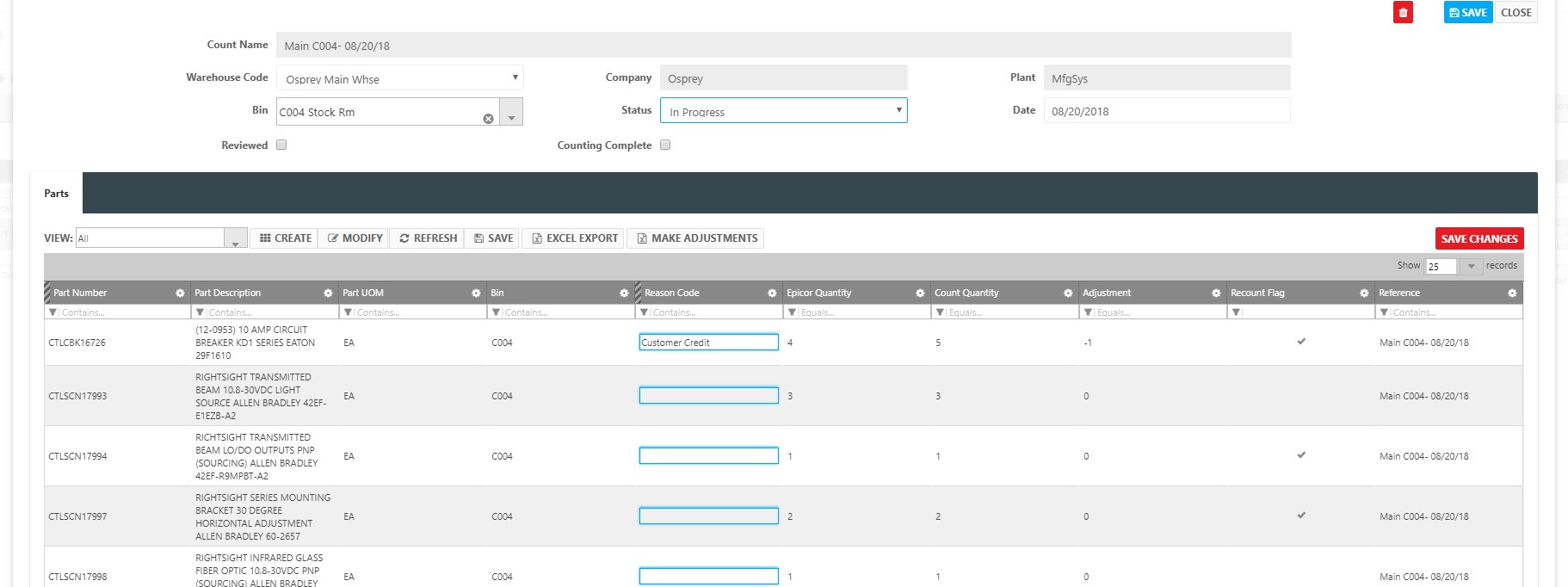

Building the inventory count – Access to the Physical Inventory Count solution is based on roles and permissions for employees managing the counts and employees counting in the warehouse. The workflow starts when the manager creates a physical count for a combination of bins and parts in a warehouse in Epicor. The solution builds a list of parts with all the information pulled from Epicor. Real-time views of data show parts information and what has been counted and recounted. Views of data show the on-hand quantities in Epicor and the actual quantities counted for review.

Working with scanners – Handheld barcode scanners connect to the front-office application, not to Epicor. This streamlined approach enables a simple, controlled counting tool for warehouse employees. Employees log in and select their count from a list of counts created by the manager. They are restricted to enter quantities for only the parts in the count. The handheld application allows the warehouse employee to move through the bins that are most efficient to them. A second counting option shows any parts that were missed or selected for a recount. The part quantities are automatically sent to the solution’s database for real-time reviews by managers in the web application.

Working with scanners – Handheld barcode scanners connect to the front-office application, not to Epicor. This streamlined approach enables a simple, controlled counting tool for warehouse employees. Employees log in and select their count from a list of counts created by the manager. They are restricted to enter quantities for only the parts in the count. The handheld application allows the warehouse employee to move through the bins that are most efficient to them. A second counting option shows any parts that were missed or selected for a recount. The part quantities are automatically sent to the solution’s database for real-time reviews by managers in the web application.

Finalizing the data – When the counting is complete, managers use the web application to review the data. If necessary, managers can pick individual parts that need a recount. They select inventory adjustment reason codes from the list of codes in Epicor. When the count is approved, the manager generates the adjustments. The solution builds a Microsoft Excel workbook for the DMT upload. Alternatively, the solution can update the inventory quantities automatically if DMT is not desired.

Continuous inventory counting – TwinEngines Physical Inventory Count solution allows warehouse employees to always be counting. Salespeople can continue to enter orders in Epicor even though the physical inventory count adjustments may not have been updated in Epicor. Shop floor employees can continue to receive parts from vendors and issue parts to jobs. Best of all, manufacturing can continue without having to wait for the Epicor ERP system to update.

ERP systems are often not flexible enough to meet the specific roles and rules of a company’s inventory control operations.