FARC personnel were spending 30+ hours per month on data entry that could be automated with Real World AI.

Overview

First American Resources Company (FARC), as part of the HUEHOCO GROUP, supplies coated steel coils for the automotive and construction industries. The company produces more than 35,000 tons per year of rolled steel that can be custom-coated and slit to customer specifications.

As part of the automotive supply chain, all materials received from vendors and shipped to customers must meet strict traceability requirements.

The Data Entry Challenge

FARC receives 300+ lots of material per month and is required to record 15-20 mechanical and chemical properties for each of these lots. Their personnel were spending 5-10 minutes per lot entering this data into PLEX. That translates to roughly 30+ hours per month on data entry alone. The potential for data entry errors when transcribing the data into PLEX was also a consideration.

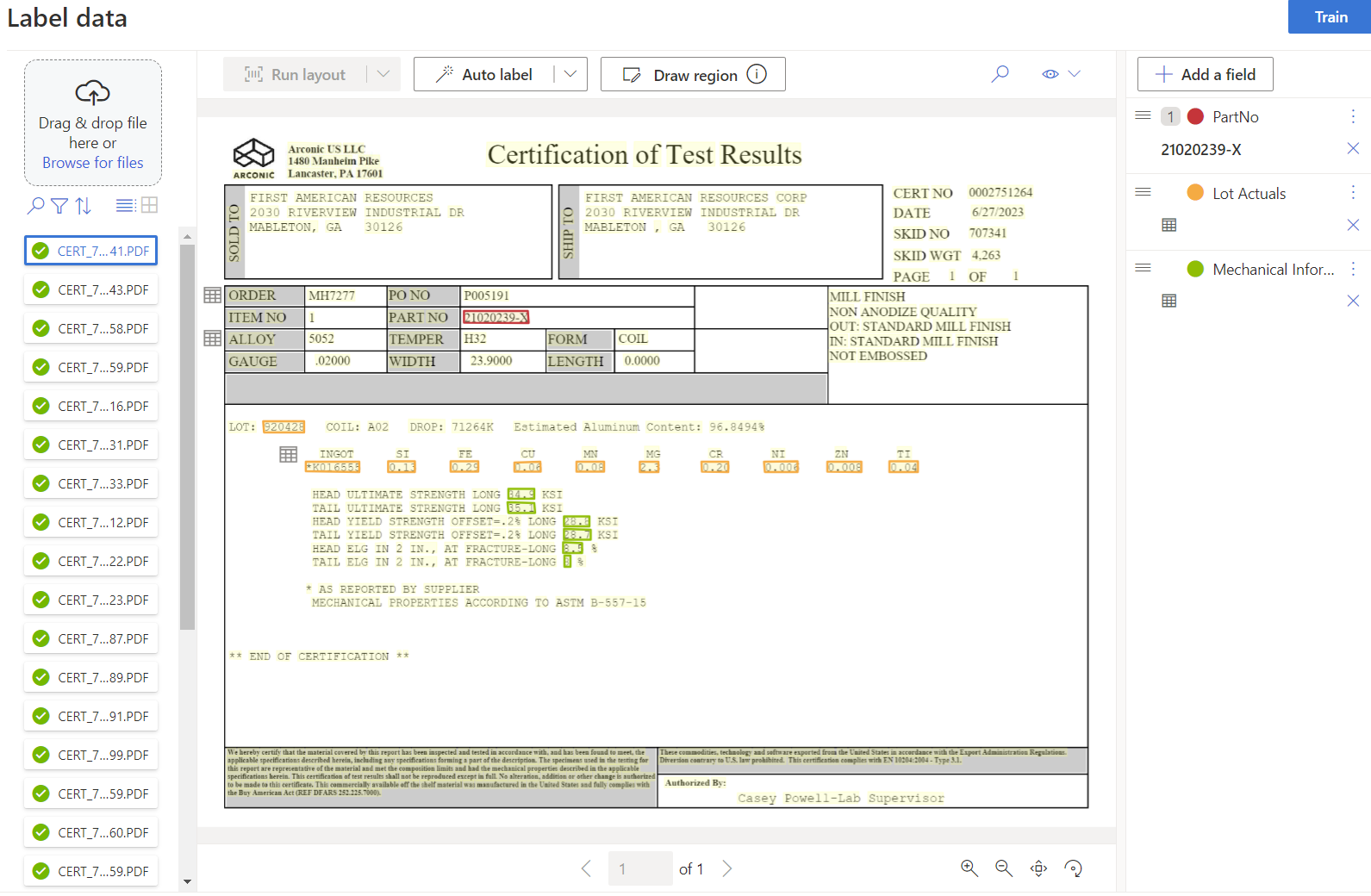

Azure Document Intelligence Studio

Azure Document Intelligence Studio was designed to automate data capture from PDFs and other documents. This cloud-based AI service uses machine learning to automate the extraction of data from electronic documents. It’s designed as a developer tool for use within custom-built applications and workflows.

The TwinEngines Solution

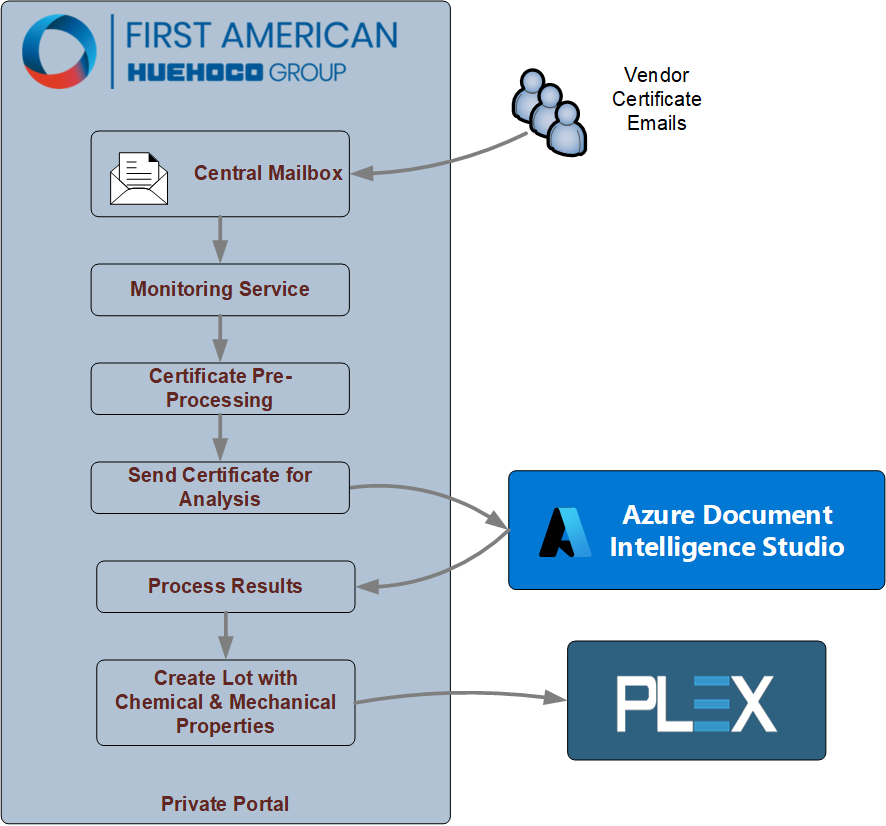

TwinEngines designed a workflow to take certificates received from multiple vendors, identify the Lot #, and extract the mechanical and chemical properties. We could then use APIs for FARC’s PLEX ERP system to automate the creation of the lot, including all the mechanical and chemical properties retrieved from the certificate.

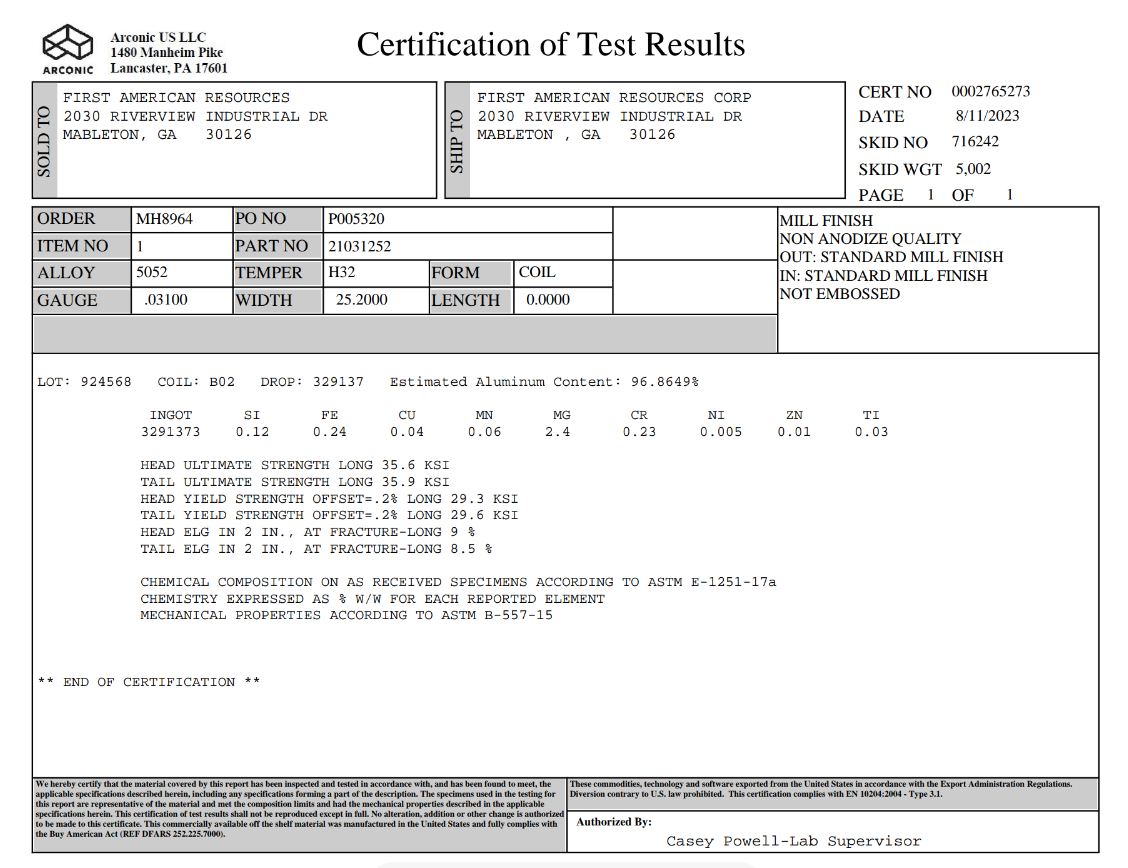

Here is an example certificate from one vendor:

Working With Formats

Each vendor uses different document formats. Depending on the material being received, the mechanical and chemical properties could also differ.

The first step was creating a unique Document Intelligence Studio model for each vendor. Multiple sample certificates were added to “train” the model to recognize the data elements we wanted to extract.

Consolidating Received Documents

TwinEngines established a central email inbox for vendors. The system monitors this mailbox for new certificates. The “From” email address identifies the vendor, which triggers which pre-programmed model to use for the data extraction. The results from the Document Intelligence Studio are returned in a JSON format, which seamlessly call PLEX APIs to capture the LOT data and mechanical and chemical properties.

The Challenges of Multiple Files

The workflow faced a few challenges caused by the different vendor formats. The Document Intelligence Studio can process one document/certificate at a time, but many vendors send a single PDF file with multiple certificates. This required pre-processing PDF files to split them into individual certificates. This was accomplished by looking for keywords that would signify the start of a new certificate and then splitting the file at that location.

The Need for OCR

An added challenge was that some of the PDF files used images instead of text. For those vendors, we ran the PDF file through an Optical Character Recognition (OCR) program first to extract the text. Then, we could search for the keywords to determine where to split the file and break out the individual certificates.

Results

FARC is now saving 30+ hours per month by not having to manually enter the 300+ lots and the dozens of mechanical and chemical properties required for each lot. By removing the manual transcribing process, our AI workflow has also eliminated the potential for data entry errors.

TECHNOLOGY

- Microsoft Dynamics Customer Engagement (CE)

- Azure AI Custom Vision

- .NET MVC Web Application

- SQL Server

- SQL Server Reporting Services

- PLEX ERP System

FARC is now saving 30+ hours per month by not having to manually enter data for more than 300 lots plus dozens of mechanical and chemical properties.

Kevin Seefried

TwinEngines President

Schedule 30 minutes to transform your business.

Arrange a meeting with a Solution Architect to streamline your operations.