Habasit America Overview

Habasit America is the world leader in industrial belts used in a wide range of industries. Unlike the handful of belts in a car, industrial applications use myriads of unique belts – conveyor belts, power transmission belts, timing belts, and more – beyond what a typical catalog can manage efficiently.

The Challenges

Habasit America faced several challenges with its customer experience and production workflow:

- Customer-Driven Product Configuration – Habasit America could configure custom orders within the Epicor Kinetic ERP but needed a CPQ web-based tool for customers, distributors, and sales support employees. Configuring products within the ERP was complex and lacked validation. Customers needed a simple tool that led them to the correct configurations and could handle the myriad of variations available for an individual part. The Epicor Kinetics CPQ tool was not a good fit for customizing belts.

- Multiple Plants – Habasit America has multiple plants in the United States – when a customer places an order a unique multi-site order management function is needed to determine where the parts are manufactured and shipped from. Epicor Kinetics’ method did not meet the business rules and performance metrics required.

- Inventory Allocation – Customers order modular plastic belt systems weeks and months in advance. To meet future shipping dates, soft allocation of future inventory needs was required to fill a gap in Epicor Kinetics – reserving inventory without tying it up.

- Re-orders – Configuring a custom part was half of the challenge. The company needed a simple way to re-order the belt without reconfiguring the same part in Epicor Kinetics.

- Optimizing Inventory – Belt manufacturing requires slitting material and joining the ends together. With different orders requiring a variety of lengths, widths, and thicknesses of material, a solution was needed to create a visual slit map to optimize material usage.

The TwinEngines Solution

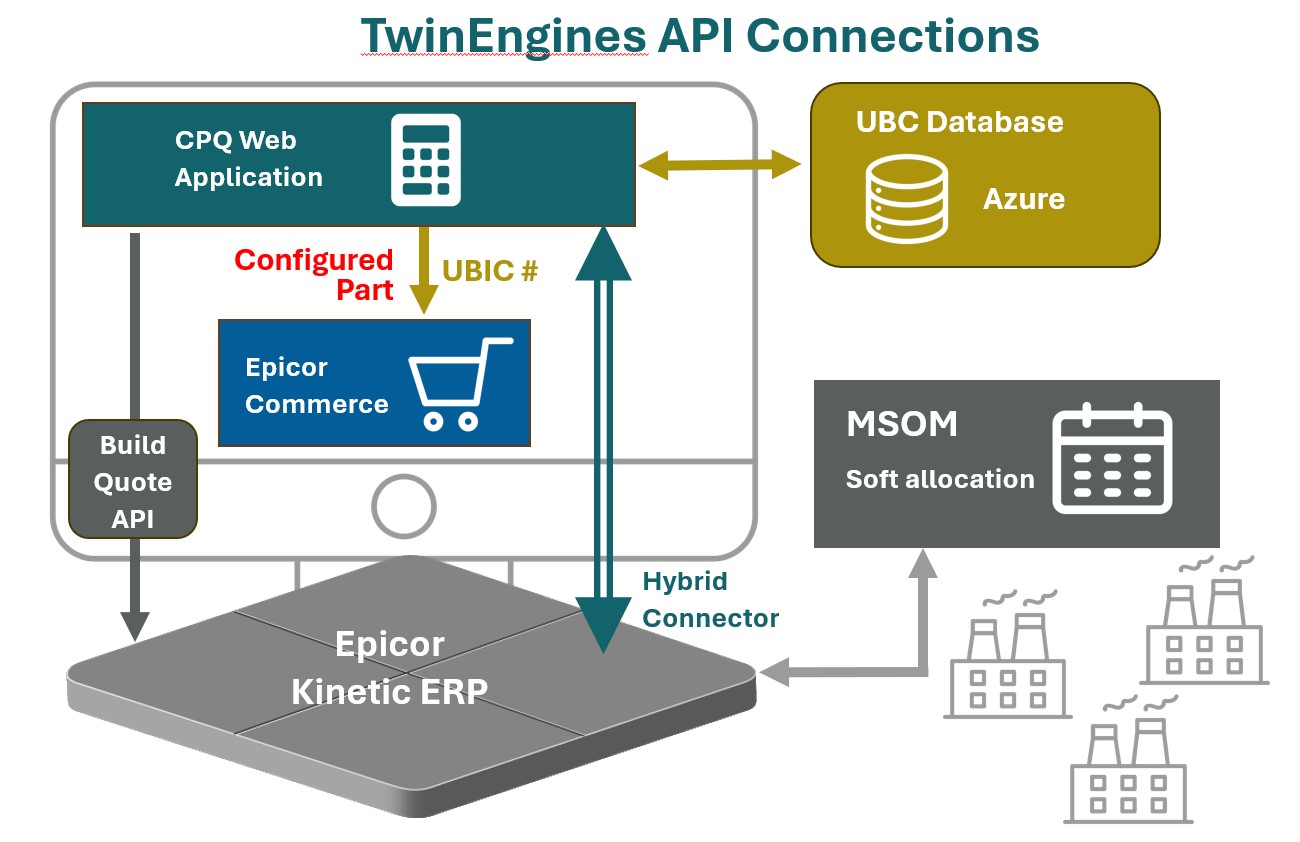

TwinEngines developed a variety of DLLs and APIs to create an integrated customer experience and production workflow. The specific components included:

TECHNOLOGY

- MS C#

- .Net and AngularJS

- SQL Server and Azure SQL Server

- Azure Web Apps

- Azure Hybrid Connections

INTEGRATIONS

- Epicor Kinetics ERP

- Epicor Commerce

“Today, manufacturing and supply chain companies are leveraging digital transformation – even at the level of cutting material on the shop floor.”

Kevin Seefried

TwinEngines President

Modules

The TwinEngines solution enhanced the customer experience and production efficiency at every job stage. The main components include:

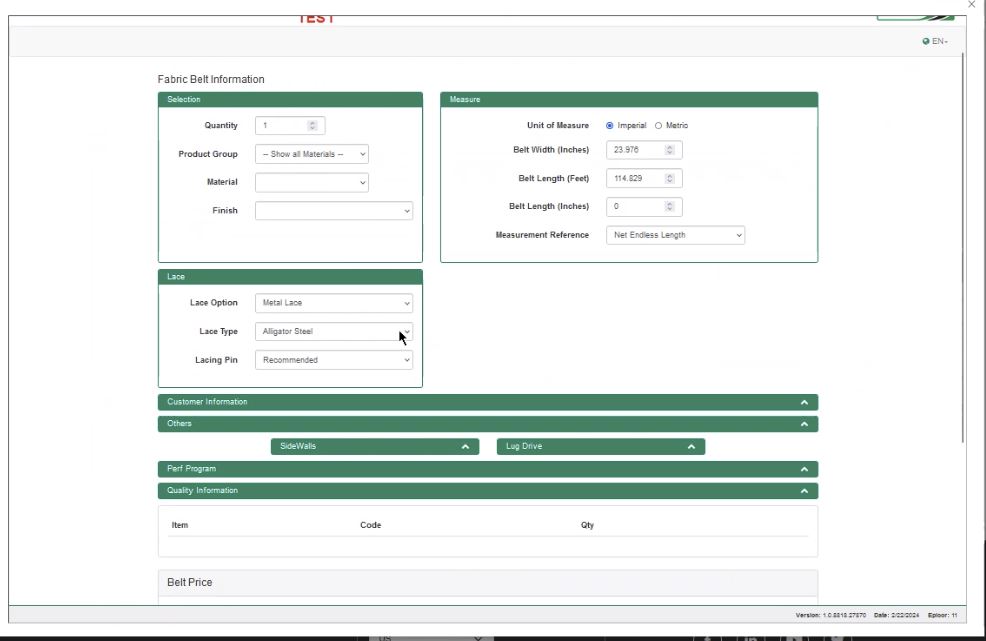

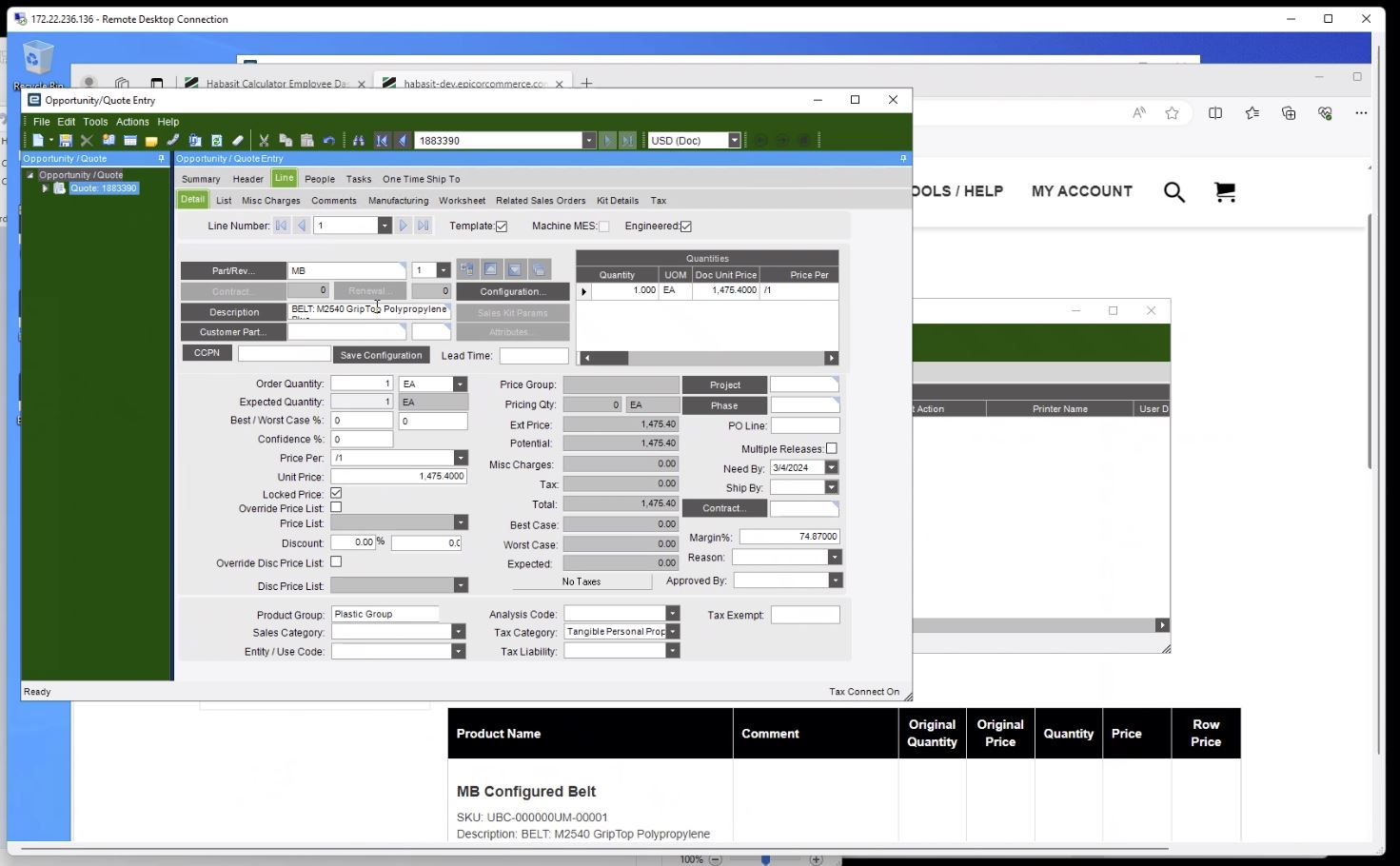

CPQ – Configure Price Quote

TwinEngines developed a CPQ to allow customers, salespeople, remote salespeople, and even customer service reps to configure belts and generate quotes and orders. Tight integration with Epicor Commerce combines the configuration process and order management into a single interface hosted in Azure.

The CPQ web app connects to Epicor through a Hybrid Connection. This VPN tunnel allows CPQ and Epicor to function as a single, consistent application over the Internet

UBC Database

TwinEngines developed APIs to create UBC parts in the Microsoft Azure database and to retrieve them from other business systems. The backbone of the custom configuration solution is the TwinEngines-designed Universal Belt Configuration database. This new product number scheme creates a consistent and repeatable part configuration process that defines a belt from hundreds of characteristics.

Prior to UBC, Habasit America created a detailed description for each ordered product. Without a unique identifier, a simple reorder would require repeating the entire configuration process. Now existing part configurations can be easily viewed by customers and orders created without additional steps to re-configure the parts for the ERP.

E-Commerce

Habasit America uses Epicor Commerce as its eCommerce solution.

TwinEngines integrated Epicor Commerce with the CPQ web application in Azure and connected it with the UBIC database. Every part configured in CPQ creates a UBIC entry in the database and is available for order in Epicor Commerce.

MSOM Multi-Site Order Management

Deliverability is a cornerstone of customer satisfaction, especially in an industrial environment where accurate shipping estimates are critical. This is a challenge for any ERP system that deals with multiple manufacturing plants, order queues, and availability of raw material.

TwinEngines developed a customized MSOM solution that instructs Epicor to recommend plants, check inventories, create a soft allocation of raw materials, and return a shipping date for the customer.

Raw Material Optimization

TwinEngines developed a rules-based fabric selection function that helps operators determine the best lots in inventory to use on orders and visually maps the parts to be cut to optimize material usage.

TwinEngines connected Epicor ERP and Epicor Commerce applications with the CPQ tool and UBC database, and added MSOM customizations to Epicor to create a fully integrated order management platform.

Results

Habasit America is part of a multinational company that uses Epicor in the USA market. TwinEngines’ UBC part ID system was so effective that the company is integrating it with its SAP operations internationally.

“The TwinEngines approach for integrating proprietary workflows into the ERP using APIs didn’t end with the CPQ product configurator,” said Kevin Seefried TwinEngines President. “We also applied this approach to a coil slitting tool. This optimization tool creates a visual map of the orders and finds the most efficient cutting layout. The map gets printed with the job packet and used by the operator on the floor. Today, manufacturing and supply chain companies are leveraging digital transformation – even at the level of cutting material on the shop floor.”