OVERVIEW

Since 1974, Osprey Corporation has remained the global leader in air filtration systems, waste handling, and recycling systems for tissue products, disposable diapers, plastic products, and more. Osprey’s engineer-to-order manufacturing process comprises unique workflows dependent upon efficient coordination and the velocity of information between sales, engineering, purchasing, production, and field services.

When a new ERP system was selected, Osprey found that all their workflows did not “fit” in the ERP system. TwinEngines built the OspreyNet portal based on the TwinEngine platform to fill the gaps with seamless integration using the ERP system’s APIs.

MOVING FROM AN OUTDATED SYSTEM

The scale and complexity of Osprey’s engineer-to-order process require customized software to manage the flow of information. The company relied on a heavily modified version of Open Systems Accounting Software (OSAS) and Excel spreadsheets for many years. OSAS, a transaction-based system that only operated on Windows XP, could not easily handle design changes after the drawings had been released into production, causing delays and rework.

The “cobbled-together” system could not be updated to work with modern software. The volume of emails with spreadsheet attachments became too unwieldy to manage operations.

GAP ANALYSIS WITH EPICOR ERP

Osprey chose Epicor for its new ERP system and asked TwinEngines to manage the implementation. During the implementation project, TwinEngines worked with Osprey managers and Epicor consultants to conduct a gap analysis identifying unique workflows Epicor could not handle effectively.

Identifying these gaps and building Web-based apps on the TwinEngines platform tightly integrated with the ERP system is often the simplest way to achieve digital transformation.

“We look for key junctures in the workflow where there are manual steps or siloed apps due to gaps in the ERP system,” Jack Burnett, Digital Transformation Lead for TwinEngines, explained. “By managing these critical tasks through dedicated Web-based applications and connecting to the ERP through APIs, we can run the operations on an end-to-end, integrated platform.”

TwinEngines and Osprey identified four significant “gaps” to be filled initially:

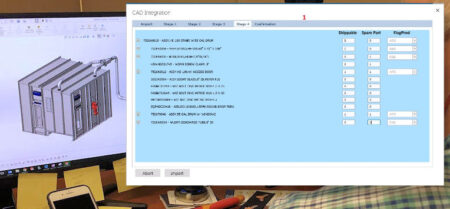

GAP 1: BUILDING THE CAD LINK

A manually intensive and time-consuming part of Osprey’s production process is the engineering workflow to design and create the parts, create the jobs for manufacturing, and then release the jobs to the shop floor. An essential step is converting CAD drawings data into ERP parts and Bills of Materials. Epicor’s engineering modules are not a good fit for Osprey, so TwinEngines built a web application for engineers to upload AutoCAD and SolidWorks data and automate the steps to create new parts and build the Bill of Materials in the ERP. Additionally, the web app allows the engineers to quickly release and re-release jobs to the shop floor when changes occur.

The legacy OSAS system did not allow changes on the fly once the engineered drawing was released into production. Even small changes required adjustments to the drawing package to be re-released for a new parts list. This “feedback loop” sent jobs back to engineering, hampered productivity, and introduced quality control issues into the production process.

“If there were five-hundred line items and we ended up with 492, we would only discover this during pre-assembly before sending it to the customer,” Sean Wallace, Osprey’s Controller, explained. “As a result, our quality control was at the back end of the production process, which was highly inefficient.”

The CAD link provided the automation to streamline engineering workflows and the visibility needed for tighter quality control, helping keep all stages of production in sync.

GAP 2: IN-HOUSE VERSUS OUTSOURCED PARTS

Osprey depends upon a flexible manufacturing model to make parts in-house or outsource to vendors. This flexibility helps manage production resources across projects and sourcing identical parts and services from preselected suppliers.

Epicor’s limitation to define a part as either manufactured or purchased was identified as a constraint to Osprey’s model. TwinEngines created a way to choose sourcing on a job in progress without creating an additional part number and bill of materials.

“We certainly didn’t want to have two parts in the Epicor parts master just to handle whether it would be outsourced,” Brian Roberson, Osprey’s engineering manager, explained. “Changing the bill of materials on the fly during production would have been time-consuming and complicated. With the OspreyNet portal, one click allows the software to do everything on the back end.”

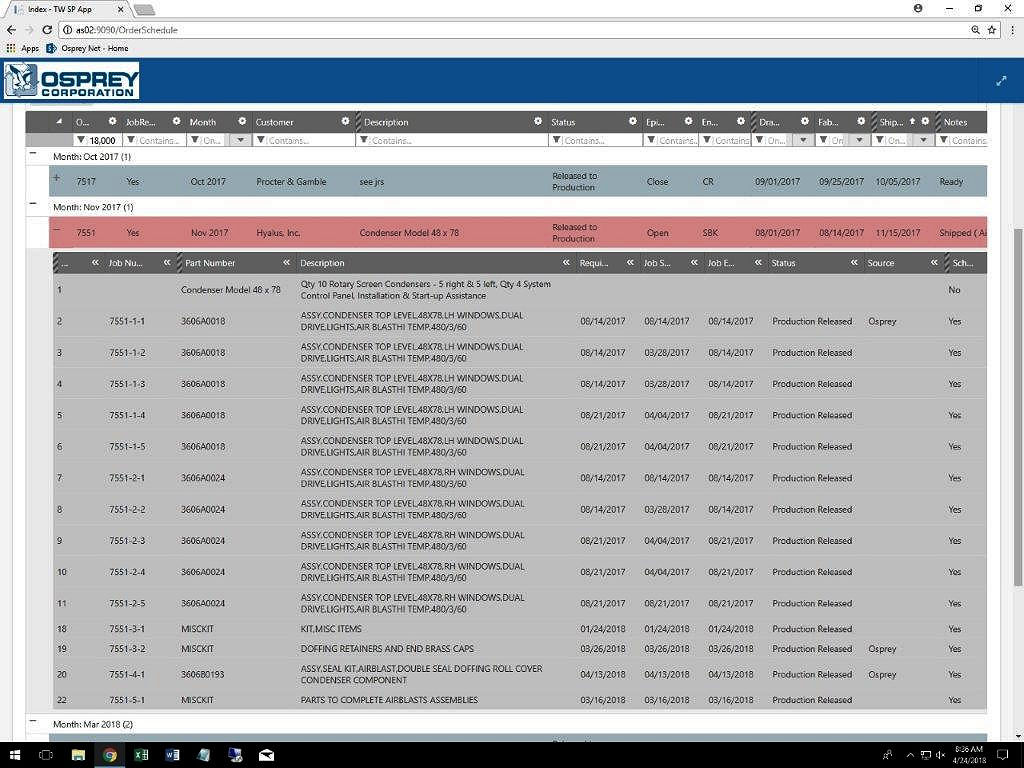

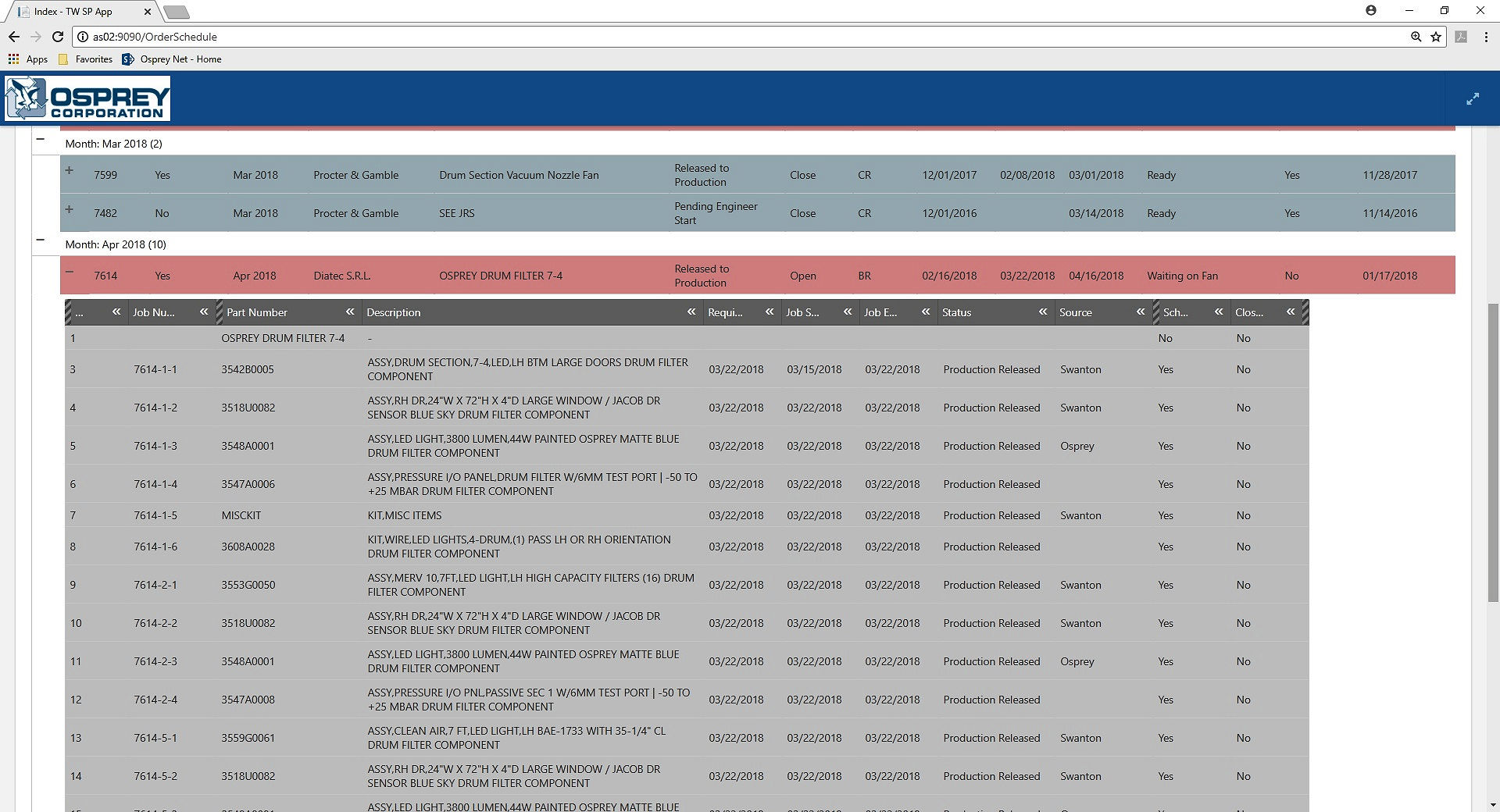

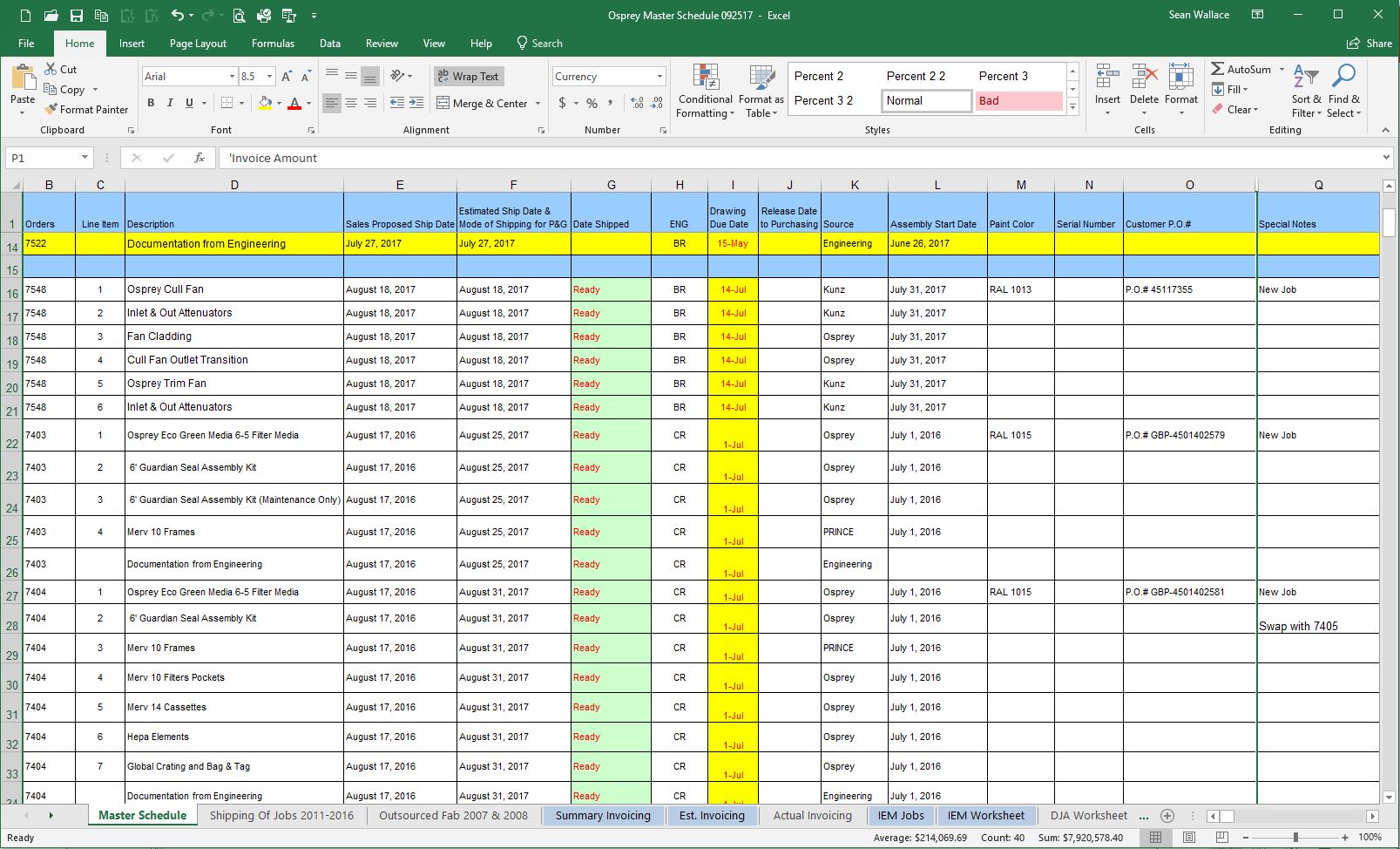

GAP 3: SCHEDULING

Scheduling was originally handled by a complex, multi-tabbed Excel workbook (see right). Managing the data in the spreadsheets was nearly a full-time job, and the workbook was outdated soon after being emailed to the team leads.

Scheduling was originally handled by a complex, multi-tabbed Excel workbook (see right). Managing the data in the spreadsheets was nearly a full-time job, and the workbook was outdated soon after being emailed to the team leads.

ERP scheduling is built around Epicor jobs and the “need by date” – when the customer needs to take delivery. For Osprey, the final product is built from multiple sub-assemblies, and they must arrive by a “fabrication due date” to meet the Q/A and shipping workflows that follow. For Osprey, some assemblies are approved before others by the customer, some assemblies are built in-house, and others come from outside fabricators. Sending purchase orders for the long lead time items is critical, and pre-assembly for Q/A has resource and space restrictions. TwinEngines created a scheduler integrated to Epicor with custom functionality to manage all aspects of the Osprey production process, including the visibility the operations management team needed to identify problems early on.

“We don’t have a traditional business where an order comes in, and we have sixteen weeks to ship it out,” Sean Wallace explained. We usually get a defined ship date from the customer, and then we must back out each due date – drawings, fabrication, outsourced assemblies, etc. With the OspreyNet portal, we enter our key dates, and the system does the scheduling. And we can flip to a capacity planning mode to analyze what-if scenarios for new business opportunities.”

GAP 4: Q/A AND SHIPPING COMPARISON

Each major assembly in a filtration system has its own quality checklist and information. The checklists are built by the OspreyNet portal as engineers define the specifications and parts and vendors, and customers provide their data. Q/A staff completes the digital checklist and after an approvals process, the equipment system is ready to ship.

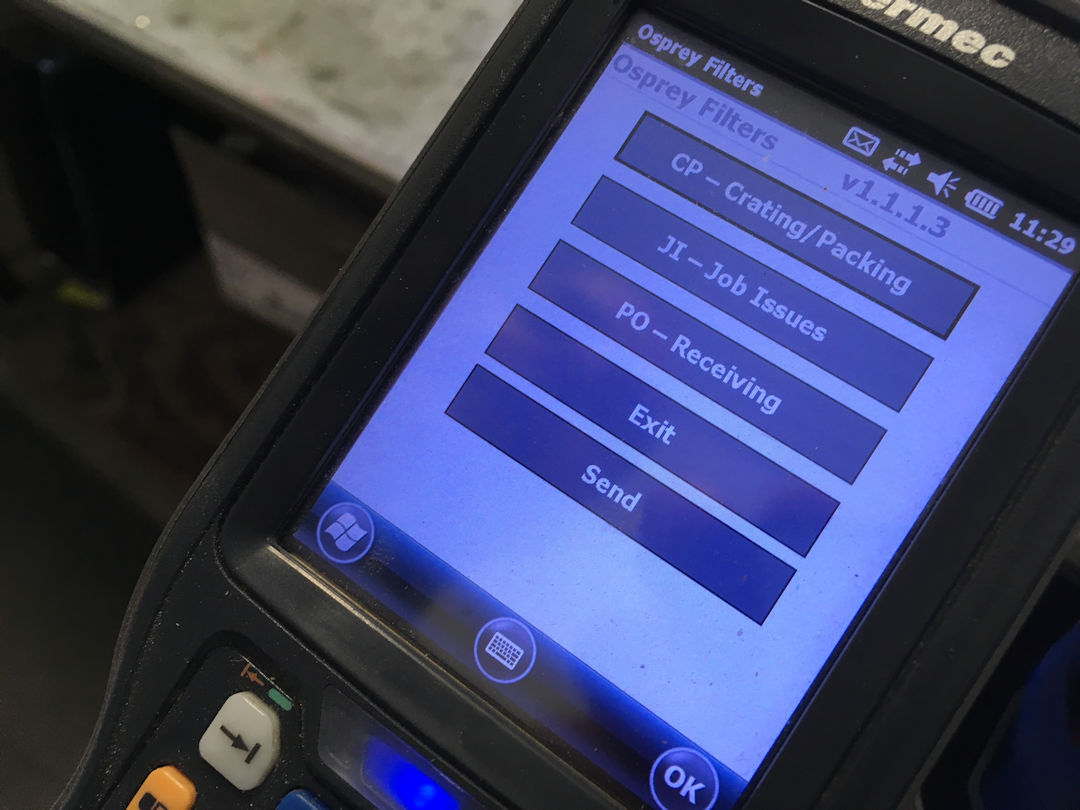

With so many parts and sub-assemblies in a completed filtration system, a final comparison of what is loaded into the crates before shipping was needed. TwinEngines created a web application and a barcode scanning program where every sub-assembly and part is scanned and compared to the shipping list built during the CAD Link import. All changes during production are automatically accounted to establish an accurate Bill of Materials.

“The barcode scanning program gives us quality assurance that we’re not missing anything, or something may have been pulled from the wrong bin,” Sean Wallace explained. “Having all the quality checklists and engineering specification documents all in one place makes it easier to work with our customers and vendors.”

PRODUCTIVITY GAINS

“We used to expect a three-to-four-week cycle to take a sales order, do the engineering, and release it into production,” Brian Roberson explained. “Today, if I don’t have an approval drawing released to a customer in two days, something’s wrong. When I started, there were five project engineers, and today we have two. We’re able to be able to do all our projects with half the workforce. The structure we set up, the engineering workflow, and the ability to integrate every component has made the difference.”

THE PATH TO DIGITAL TRANSFORMATION

Osprey began its ERP project to replace outdated accounting software and individual spreadsheets. What started as a collection of gap-filling modules evolved into an integrated platform called OspreyNet to manage the processes from sales through engineering, production, and shipping, to field services. Other gaps solved in our continuous improvement approach include:

- PO automation for sub-contract services

- Non-conformance tracking

- Customer service issue management

- Physical inventory counts

- Field service management

- Spare parts sales analysis.

CLIENTS SEE RESULTS

“We didn’t realize that this project would have the dramatic effect it did,” Sean Wallace explained. “We never dreamed that we would be able to get rid of our hands-on quality control process, but that’s what happened. That quality control is now built into the OspreyNet system and with each engineering release. We’re getting better data to the sales reps, and we no longer need to go through every piece of equipment we sold that month to ensure it was priced correctly. TwinEngines has transformed our business.”

TECHNOLOGY

- Microsoft Visual Studio, C#, .Net

- SQL Server

- SQL Reporting Services (SSRS)

- Power BI

INTEGRATIONS

- Epicor Kinetics ERP

- Microsoft 365

- SolidWorks

List of jobs in the Production Schedule

Component parts of a job in the Production Schedule

“That quality control is now built into the Osprey Net system and with each engineering release,” said Sean Wallace of Osprey. “We’re getting better data to the sales reps, and we no longer need to go through every piece of equipment we sold that month to ensure it was priced correctly. TwinEngines has transformed our business.”