THE CHALLENGE OF CUSTOM POOL LINERS

Tara Liners, an Alabama manufacturer of custom vinyl pool liners, works through a network of pool dealers and distributors to sell pool liners for standard pools and nearly 20 custom pool shapes. The existing system used a unique order form for each type of liner. Customers found selecting and completing the correct form and completing to be complicated.

Once completed, the form directed the custom manufacturing process. The form data was manually entered into the ERP to guide CAD, scheduling, production, and shipping. Dealers and distributors could not access Tara’s ERP system, which produced data entry errors, increased customer support needs, and delayed deliveries. Even a simple typo led to back-and-forth phone calls and faxes – sometimes forcing the distributor to make a second trip to the pool to measure.

THE WEB PORTAL SOLUTION

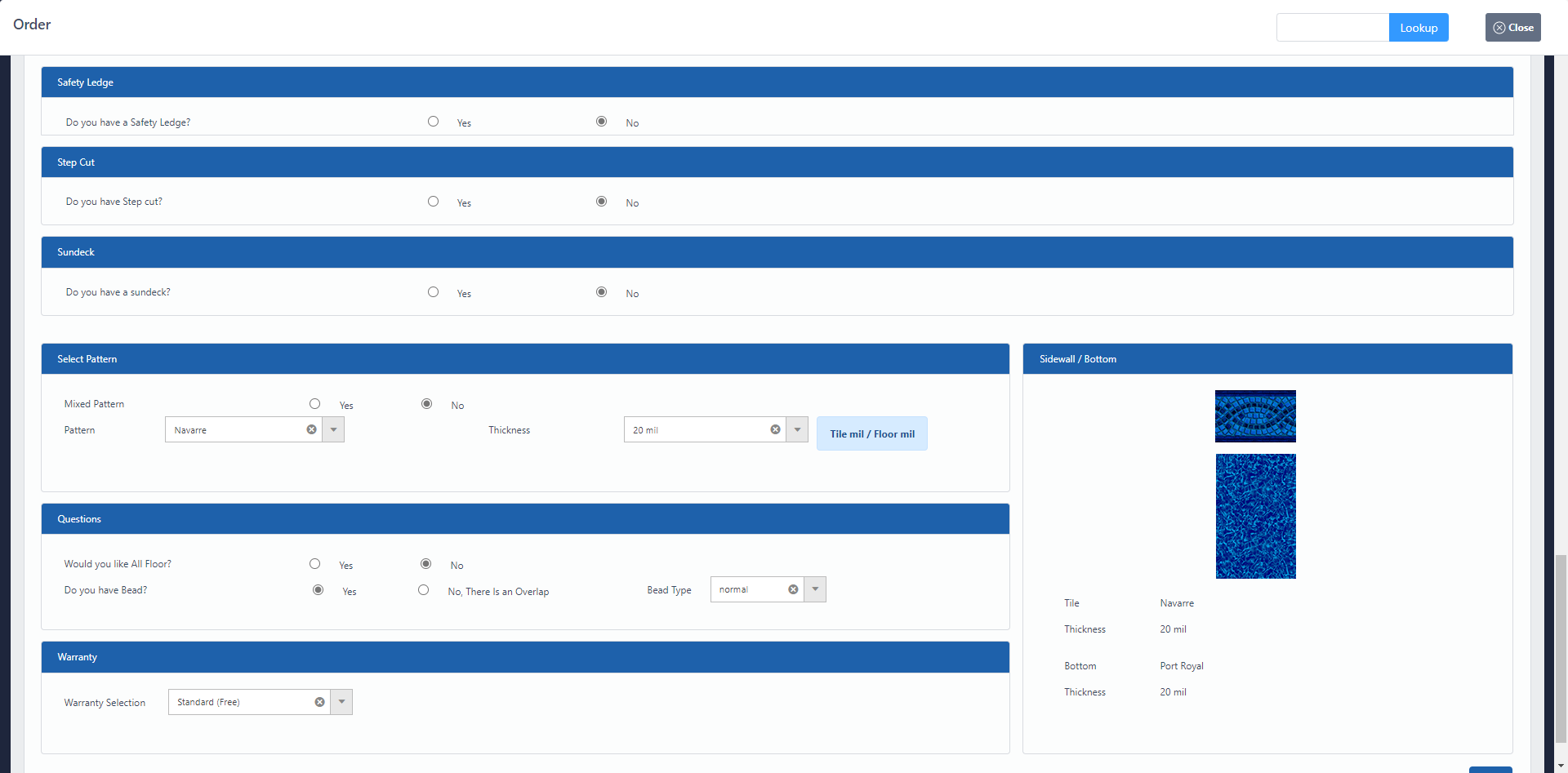

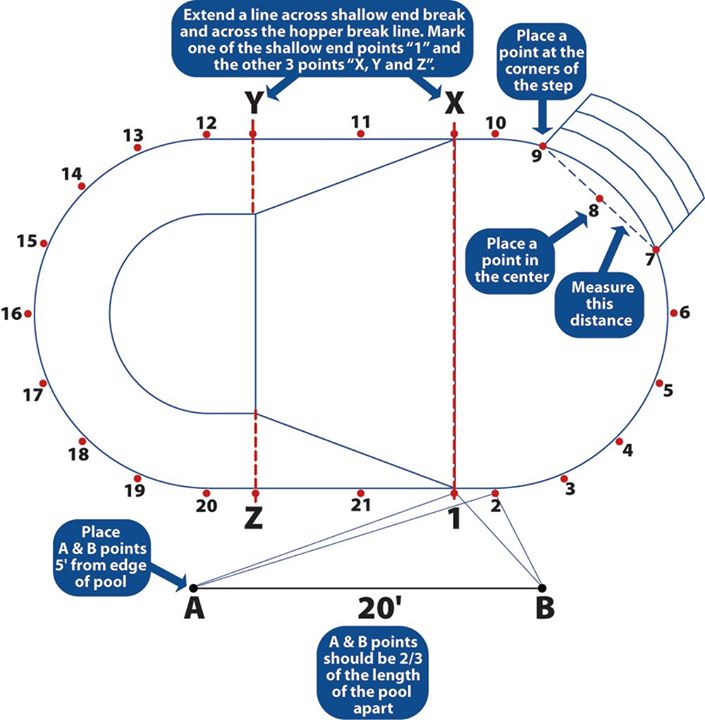

TwinEngines developed a dealer/distributor Web portal named Tara 24/7 that integrated the order/manufacturing process with Tara’s Fourth Shift ERP system. The portal streamlined the order process, configured liners, tracked orders, and managed quotes. A dynamic configuration tool displayed the pool layout with measurements to ensure accurate, one-time data entry to eliminate errors.

CAD INTEGRATION

CAD INTEGRATION

Tara expedites all orders, often shipping the same day the order was placed. Direct integration of the AutoCAD system allowed field measurements to flow into the portal and ERP. “AutoCAD writes to our tables in the portal, and we use that data for pricing and manufacturing,” explains TwinEngines’ Director of U.S. Operations, Mike Losapio.

RESULTS

With the portal, when a customer requests a quote, the system automatically calculates costs based on an algorithm that factors the pool’s shape and dimensions. Dealers associated with a distributor can place their orders directly, after which their representative finalizes the order.

The system keeps sales orders, customer data, pool shape, and order status synchronized between the Tara 24/7 portal and the ERP system. All orders, including by phone and fax, can be accessed, allowing customers to track their jobs from the initial order to manufacturing and shipment. As a result, the seamless workflow has shortened the sales and manufacturing cycle.

MOVING TO THE CLOUD

The Fourth Shift ERP system performed well for several years until Tara decided to move to the cloud. After reviewing several ERPs that focused on manufacturing, Tara chose Oracle’s NetSuite. “We chose NetSuite over other ERP systems for its customization ability to fit our company’s processes,” Matt Lassiter, Tara’s CFO, explained.

NetSuite offered superior inventory tracking for custom projects,” said TwinEngine’s Losapio. “We can send a Bill of Materials into an actual work order and populate the quantities. By pushing the order data from the portal into NetSuite, we can now maintain an accurate inventory, which they’ve never been able to do before.”

END-TO-END VISIBILITY

The integrated system offers visibility from the initial order through manufacturing and shipping. Dealers, distributors, the shop floor, and back office personnel are connected in real time. “As they schedule and manufacture the liner, all of that data flows back into the portal,” Losapio explained. “Dealers and distributors can see when their job is scheduled to be cut and delivered. It offers a great boost to productivity and customer satisfaction.”